Aluminium Recycling Services |

Recyclability of Aluminium

Let’s Recycle It Aluminium Recycling Services

Let’s Recycle It has a team of experts in metals, recycling, logistics, and international compliance. This positions us perfectly to be able to help you with your aluminium needs, whether they are finding outlets for your aluminium waste, sourcing aluminium scrap, or finding supply of recycled aluminium. If you need to buy or sell scrap or recycled aluminium, contact Let’s Recycle It today.

Aluminium Recycling

Aluminium recycling services play a crucial role in the circular economy, transforming waste into valuable resources. Recycling aluminium is not just about sustainability; it's a testament to the material's endless recyclability. Aluminium, known for its durability and lightweight nature, can be recycled repeatedly without losing its quality. This process conserves energy, reduces greenhouse gas emissions, and saves raw materials, making it a cornerstone of environmental stewardship. As we delve into the nuances of aluminium recycling, we uncover its significant benefits for the planet and our future.

The Essentials of Recycling Aluminium

Recycling aluminium is a straightforward yet impactful process. It begins with the collection of aluminium products, ranging from cans to foil and automotive parts. These items are then transported to recycling facilities where they undergo sorting to remove any non-aluminium components. The clean aluminium is melted in a furnace, a process that requires a fraction of the energy needed to produce new aluminium. This molten aluminium is then cast into ingots, ready to be made into new products. Recycling aluminium not only conserves resources but also supports the economy by providing jobs in the recycling and manufacturing sectors.

By focusing on the essentials of recycling aluminium, we highlight the importance of this material in achieving sustainability goals. Through efficient recycling practices, we can significantly reduce our environmental footprint, underscoring the critical role that aluminium recyclers play in our society.

Discovering Aluminium Recyclers

Aluminium recyclers are at the heart of the recycling chain, offering a bridge between waste and new beginnings for aluminium materials. These recyclers specialise in processing aluminium scrap, turning it into high-quality aluminium that can be used anew. Their work not only contributes significantly to environmental conservation but also propels the economy by supplying the manufacturing sector with essential raw materials. Finding a reliable aluminium recycler involves looking for those who adhere to the highest standards of environmental compliance and who can demonstrate a transparent supply chain. This ensures that the aluminium recycling process is as efficient and effective as possible, contributing to a reduction in global mining demands and promoting a more sustainable approach to resource management.

The Life Cycle of Recycled Aluminium

The journey of recycled aluminium illustrates the beauty of sustainability in action. This process starts with the collection of aluminium scrap, including common items like beverage cans and automotive parts. Once gathered, the aluminium undergoes a meticulous sorting process to ensure purity before it's melted down. The melting process, significantly more energy-efficient than producing new aluminium, results in a liquid form that can be moulded into new products. This cycle, emblematic of recycled aluminium's life, showcases not only the material's durability but also its adaptability. Through recycling, aluminium finds new life in various forms, from transportation to packaging, underlining the metal's versatility and the critical role of recycling in our pursuit of sustainability.

Simplifying Aluminium Can Recycling

Simplifying aluminium can recycling is both an effortless and impactful endeavour. By highlighting the straightforward nature of aluminium can recycling with Let’s Recycle It, we underline how little effort is needed to significantly benefit the environment. The process involves simple steps from preparing the cans for recycling to comprehending their recycling journey, aiming to boost widespread participation. Emphasising such simplicity not only promotes a culture of recycling but also draws attention to its concrete advantages, including the conservation of resources and the reduction of the environmental footprint. Through this, we see how an uncomplicated action can lead to substantial environmental gains.

Advancements in Recycling Aluminium Technology

The evolution of technology in the realm of aluminium recycling marks a significant leap towards environmental conservation and efficiency. Modern advancements have paved the way for more sophisticated recycling methods, significantly enhancing the purity and quality of recycled aluminium. These technological innovations not only streamline the recycling process but also broaden the potential applications of recycled aluminium, pushing the boundaries of its use in various industries. By embracing these advancements, we underscore our commitment to sustainability and the pivotal role of cutting-edge technology in shaping a greener future.

Leading the Way in Aluminium Drinks Can Recycling

Leading the way in aluminium drinks can recycling is pivotal for environmental conservation, underlining the crucial role of innovative recycling initiatives. Successful programmes worldwide showcase the profound impact of such efforts, significantly reducing waste and energy consumption. For instance, initiatives that streamline the collection and processing of aluminium cans have demonstrated not only a decrease in landfill use but also a substantial energy savings, echoing the importance of recycling in our daily lives. These projects serve as exemplary models, inspiring communities and industries to adopt more sustainable practices in managing aluminium waste, thereby contributing to a greener planet.

Sell and Buy your

Material with Us

Your plastic information

For sales-related enquiries please use the form to the right and we will get back to you as soon as possible.

Should you require any further information on how you can benefit from recycling your waste, to discuss value or to arrange a site visit from one of our team, please do not hesitate to contact us

"*" indicates required fields

Your plastic information

For sales-related enquiries please use the form to the right and we will get back to you as soon as possible.

Should you require any further information on how you can benefit from recycling your waste, to discuss value or to arrange a site visit from one of our team, please do not hesitate to contact us

"*" indicates required fields

Materials we accept

PET Recycling

PET - PET is the abbreviation for Polyethylene Terephthalate, which is formed when ethylene glycol and terephthalic acid are combined. It is a clear plastic that is both strong and lightweight enough to be popularly used for food and beverage packaging, with close to all single-use plastic drinks bottles being made from PET. It is also a popular choice for a great many other products, such as bottles for hygiene products and even tennis ball cannisters.

HDPE Recycling

HDPE - HDPE is the abbreviation for High-Density Polyethylene, which is made from the monomer ethylene. It is a thermoplastic, which means that it can become softer when heated in order to be moulded and will then harden when cooled without any alteration to the material’s properties. The material is incredibly versatile as it is lightweight, strong, malleable, impact resistant, weather resistant and long lasting. It is used across a wide variety of products over a range of different industries. For example, it is used for milk jugs, fuel tanks, piping, children’s toys, and even bread bags and cereal box liners.

PVC Recycling

PVC - PVC is the abbreviation Polyvinyl Chloride. It is made by the combination of chlorine and ethylene to form the monomer vinyl chloride, which is then sequenced to make the polymer Polyvinyl Chloride. PVC is a very strong and tough material that can be easily shaped, which gives it many different uses in terms of what it can be manufactured into. PVC can also be made soft and flexible when mixed with certain additives. This means that whereas PVC can be used for construction, automotive and medical items, it can also be used for items such as polyvinyl flooring, clothing and upholstery.

LDPE Recycling

LDPE - LDPE is the abbreviation of Low-Density Polyethylene, which is made from the monomer ethylene. LDPE is a thermoplastic, which means that when heated it can become softer in order to be moulded and will then harden when cooled without any alteration to the material’s properties. The plastic is lightweight, strong, impact resistant and chemical resistant. LDPE is an ideal material for the manufacturing of thin, flexible products such as plastic bags, shrink-wrap, stretch film, container lids, squeezable bottles and so on.

PP Recycling

PP - PP is the abbreviation of Polypropylene, which is a thermoplastic made from the monomer propylene. Being a thermoplastic means that when heated it can become softer in order to be moulded and will then harden when cooled without any alteration to the material’s properties. PP is tough, lightweight, chemical resistant and moisture resistant. The plastic is used for a wide range of products, such as packaging products, automotive parts and consumer goods.

PS Recycling

PS - PS is the abbreviation of Polystyrene, a hydrocarbon polymer made from the monomer styrene. It is a thermoplastic, which means that when it is heated it can become soft enough to mould and then harden again when cooled. PS can come in the form of a solid plastic or a rigid foam. Solid PS is commonly used in items such as medical test tubes, household smoke alarm housings, CD cases and yoghurt pots. Foam PS is frequently used as packing material.

PC Recycling

PC - PC is the abbreviation for Polycarbonate. Polycarbonates are a group of thermoplastic polymers that contain within their chemical structure carbonate groups. PC is very strong, impact resistant, heat resistant, chemical resistant and lightweight. This plastic is commonly used in items such as parts for appliances, automotive parts, construction parts, medical gear, consumer products and food packaging.

ABS Recycling

ABS - ABS is the abbreviation of Acrylonitrile Butadiene Styrene, a polymer made from the monomers acrylonitrile, butadiene and styrene. It is stiff, strong, impact resistant and chemical resistant. It is used in a number of different products such as computer parts, tools, plug socket faces and toys.

Steel Recycling

Steel recycling converts discarded steel into new material, leveraging steel's capability to be recycled indefinitely without degradation in quality. It's essential for managing resources and energy efficiency, as recycling steel uses less energy than producing new steel from iron ore. Recycled steel is fundamental in construction, automotive industries, and manufacturing of household appliances, supporting a sustainable circular economy.

Aluminium Recycling

Aluminium recycling involves reprocessing scrap aluminium into new products, capitalising on aluminium's ability to fully retain its properties after recycling. It's a critical process due to aluminium's widespread use in cans, foils, tubes, and aeroplane parts. Recycling aluminium saves significant energy compared to primary production, reducing environmental impact and conserving the metal's availability for future use.

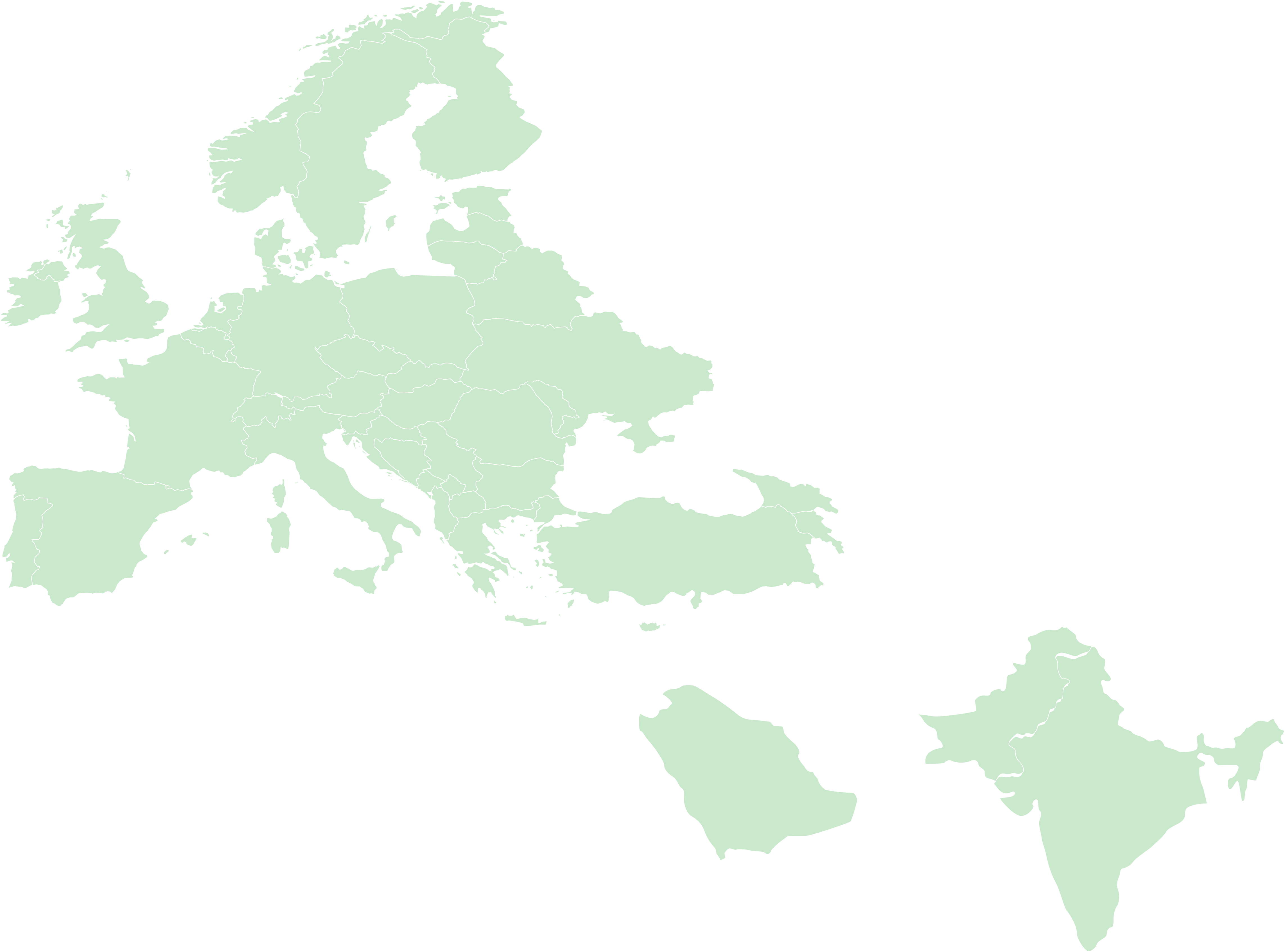

Where Let's Recycle It Operates

Countries We Cover

We pride ourselves on delivering industry unrivalled customer service, exceeding our customers' expectations across all of the countries we work in.

Ireland

- Ireland is Europe’s top producer of plastic waste per capita.

- 95% of plastic waste was exported to China until the country banned imports of waste from foreign countries in January 2018, meaning Ireland faces pressure to find alternate waste disposal methods to help them reach their 2030 goals of an 80% increase in plastic recycling.

- Ireland is placing a ban on single-use plastics coming into effect in 2021.

United Kingdom

- United Kingdom produces 5 million tonnes of plastic waste annually.

- UK set to introduce a plastic packaging tax of £200 per ton on packaging made of less than 30% recycled materials, which is expected to increase the use of recycled plastics in packaging by 40%.

- UK aims for all plastic packaging on the market to be recyclable, reusable or compostable by 2025.

France

- France produces 5 million tonnes of plastic waste annually.

- France ranks among Europe’s poorest performers in plastic recycling with a rate well below the European average, due to their insufficient domestic recycling capacity.

- France introduced a total ban on single use plastics to come into full effect in 2040 and began taking steps towards this in January 2020.

Belgium

- Belgium produces 610,000 tonnes of plastic waste annually.

- Belgium is one of the most efficient recyclers of plastic waste in Europe, recycling over 80% of their used plastic.

- Belgium is introducing a series of bans on single use plastics, which began with the ban of single use plastics at public events in Brussels.

Germany

- Germany produces 6.5 million tonnes of plastic waste annually.

- Germany has been famously known as the plastic recycling hub of Europe.

- They use ‘The Green Dot System’ whereby manufacturers and retailers must pay for a green dot on products. The more packaging they use, the higher the cost.

- Thanks to a low energy PET plastic (polyethylene terephthalate) recycling line at its plant in Rostock, Northern Germany, Veolia gives post-consumer plastic bottles a second life in a "bottle-to-bottle" cycle. One billion bottles per annum are recycled for further food use!

Poland

- Poland produces 3.4 million tonnes of plastic waste annually.

- Plastics processing is the biggest and most rapidly growing sector within the Polish plastics industry.

- Plastics processing in Poland accounts for 85% of the industry’s annual turnover; its main areas of processing include: plastic containers, bottles, packaging, pipes, automotive parts.

Hungary

- Hungary produces 740,000 tonnes of plastic waste annually.

- Hungary is one of the three worst offenders for meeting EU plastic waste recycling targets.

- Hungary is taking a number of steps to increase their plastic recycling to meet EU targets; they are introducing a single-use plastic ban in 2021 and will also introduce a tax on various other plastic items, such as straws, cups and plates.

Romania

- Romania recycles only 14% of its waste, while upwards of 70% of the waste produced is sent to landfill.

- Romania has failed to increase the percentage of the waste it recycles since 2010 and will miss the EU 2020 targets.

- In 2018, Romania was found guilty by the EU Court of Justice for failing to close and empty 68 landfill sites that were deemed to pose environmental and health hazards.

- Romania is applying for EU grants to help them invest in waste processing technology as an alternative to landfill.

Slovakia

- Slovakia recycles only 23% of its waste, while upwards of 65% of the waste produced is sent to landfill.

- Slovakia will introduce a total ban on single-use plastics in January 2021; it will be illegal to sell plastic straws, cutlery, plates etc.

- This ban is part of Slovakia’s efforts to make a shift towards using biodegradable packing materials.

Italy

- Italy produces 2.2 million tonnes of plastic waste annually.

- A report by the Italian Institute for Environmental Protection and Research in October 2019 found that more than 500,000 tonnes of plastic waste from Italy ends up in the Mediterranean Sea.

- Italy has steadily increased the amount of plastic it recycles since 2013, and the country is set to introduce a tax on plastic packaging in the summer of 2020.

Turkey

- Turkey produces 3.5 million tonnes of plastic wate annually.

- Turkey has become one of the largest importers of plastic waste as the US and Europe send more waste there since China began to close its doors to overseas recyclables, with an increase in the amount of imported plastic in Turkey of around 200% since 2016.

- Turkey’s Zero Waste Project, which began in December 2018, introduced several measures to reduce plastic consumption: for example, fees for plastic carrier bags and deposits for plastic drinking bottles.

India

- India produces 10 million tonnes of plastic waste annually, with around 4 million tonnes of it going uncollected.

- India is covered in illegal landfill sites that each cover several acres of land and hold thousands of tons plastic waste piled up several metres high, and is one of the world’s worst contributors to plastic pollution in rivers and oceans

- India introduced the Plastic Waste Management Rules in 2016, and amended them in 2018, to legislate for local authorities to be held responsible for setting up their own recycling infrastructure and for corporate responsibility on manufacturers for collecting the waste their products produce.

Pakistan

- Pakistan produces 6.5 million tonnes of plastic waste annually.

- Pakistan’s plastic industry has been growing at a staggering rate of 15% per year in Pakistan, which has led to the government introducing their plan of action to move towards a circular economy and achieve the UN’s Sustainable Development Goals for 2030.

- Pakistan is investing in its infrastructure to increase its capacity to collect and process plastic waste, especially PET single use drinking bottles.

- Regional bans have already been placed on the use of these PET single use bottles as they are one of the worst offending items contributing to Pakistan’s plastic pollution problem.

Sweden

- Sweden produces 300,000 tonnes of plastic waste annually.

- Sweden is one of the world leaders in recycling, having gone further than most other countries in moving towards a circular economy.

- Only 1% of Sweden’s annual waste goes to landfill; most of the waste is either recycled and sent back into manufacturing or is burned in low-carbon incinerators to produce energy to power anything from buses to apartment buildings.

Norway

- Norway is one of the world leaders in the recycling of plastic waste.

- Norway’s plastic drinking bottle recycling programme recycles over 97% of plastic bottles, with fewer than 1% going to landfill.

- The quality of the recycled plastic drinking bottle material is so high that 92% of bottles are used to make more bottles; the material has been reused to make new drinking bottle dozens of times in some cases.

- Norway is among the nations that send the least amount of waste to landfill; most of the waste in Norway is either recycled or burned in low-carbon incinerators to produce energy to power anything from buses to apartment buildings.

Finland

- Finland produces 380,000 tonnes of plastic waste every year.

- Finland, particularly in its cities, experienced its largest increase in the amount of plastic it recycled in 2019; in some areas recycling increased by 180% compared to 2018.

- Many housing companies in Finland have been joining the new eco-initiative to increase the amount of waste that is recycled and reduce the amount going to landfill.

Portugal

- Portugal produces 1 million tonnes of plastic waste annually.

- Portugal introduced bans on several single-use plastic items from 2020, including carrier bags and cutlery.

- Portugal is behind the EU’s recycling goals for 2020, but the country did recycle 10% more waste material in 2019 than it did compared to 2018.

Saudi Arabia

- Saudi Arabia produces 2.5 million tonnes of plastic waste annually.

- Saudi Arabia introduced new regulations for plastic in December 2017, with the second phase coming into effect in 2020, with the use of plastic being banned for several single-use products.

- Saudi Arabia is investing in new state of the art recycling facilities to mitigate the increasing demand they are set to face; with the rapidly increasing rates of population growth and urbanisation, the amount of waste Saudi Arabia produces is forecast to double by 2033.

United Kingdom

- United Kingdom produces 5 million tonnes of plastic waste annually.

- UK set to introduce a plastic packaging tax of £200 per ton on packaging made of less than 30% recycled materials, which is expected to increase the use of recycled plastics in packaging by 40%.

- UK aims for all plastic packaging on the market to be recyclable, reusable or compostable by 2025.

Belgium

- Belgium produces 610,000 tonnes of plastic waste annually.

- Belgium is one of the most efficient recyclers of plastic waste in Europe, recycling over 80% of their used plastic.

- Belgium is introducing a series of bans on single use plastics, which began with the ban of single use plastics at public events in Brussels.

Finland

- Finland produces 380,000 tonnes of plastic waste every year.

- Finland, particularly in its cities, experienced its largest increase in the amount of plastic it recycled in 2019; in some areas recycling increased by 180% compared to 2018.

- Many housing companies in Finland have been joining the new eco-initiative to increase the amount of waste that is recycled and reduce the amount going to landfill.

France

- France produces 5 million tonnes of plastic waste annually.

- France ranks among Europe’s poorest performers in plastic recycling with a rate well below the European average, due to their insufficient domestic recycling capacity.

- France introduced a total ban on single use plastics to come into full effect in 2040 and began taking steps towards this in January 2020.

Germany

- Germany produces 6.5 million tonnes of plastic waste annually.

- Germany has been famously known as the plastic recycling hub of Europe.

- They use ‘The Green Dot System’ whereby manufacturers and retailers must pay for a green dot on products. The more packaging they use, the higher the cost.

- Thanks to a low energy PET plastic (polyethylene terephthalate) recycling line at its plant in Rostock, Northern Germany, Veolia gives post-consumer plastic bottles a second life in a "bottle-to-bottle" cycle. One billion bottles per annum are recycled for further food use!

Hungary

- Hungary produces 740,000 tonnes of plastic waste annually.

- Hungary is one of the three worst offenders for meeting EU plastic waste recycling targets.

- Hungary is taking a number of steps to increase their plastic recycling to meet EU targets; they are introducing a single-use plastic ban in 2021 and will also introduce a tax on various other plastic items, such as straws, cups and plates.

India

- India produces 10 million tonnes of plastic waste annually, with around 4 million tonnes of it going uncollected.

- India is covered in illegal landfill sites that each cover several acres of land and hold thousands of tons plastic waste piled up several metres high, and is one of the world’s worst contributors to plastic pollution in rivers and oceans

- India introduced the Plastic Waste Management Rules in 2016, and amended them in 2018, to legislate for local authorities to be held responsible for setting up their own recycling infrastructure and for corporate responsibility on manufacturers for collecting the waste their products produce.

Ireland

- Ireland is Europe’s top producer of plastic waste per capita.

- 95% of plastic waste was exported to China until the country banned imports of waste from foreign countries in January 2018, meaning Ireland faces pressure to find alternate waste disposal methods to help them reach their 2030 goals of an 80% increase in plastic recycling.

- Ireland is placing a ban on single-use plastics coming into effect in 2021.

Italy

- Italy produces 2.2 million tonnes of plastic waste annually.

- A report by the Italian Institute for Environmental Protection and Research in October 2019 found that more than 500,000 tonnes of plastic waste from Italy ends up in the Mediterranean Sea.

- Italy has steadily increased the amount of plastic it recycles since 2013, and the country is set to introduce a tax on plastic packaging in the summer of 2020.

Norway

- Norway is one of the world leaders in the recycling of plastic waste.

- Norway’s plastic drinking bottle recycling programme recycles over 97% of plastic bottles, with fewer than 1% going to landfill.

- The quality of the recycled plastic drinking bottle material is so high that 92% of bottles are used to make more bottles; the material has been reused to make new drinking bottle dozens of times in some cases.

- Norway is among the nations that send the least amount of waste to landfill; most of the waste in Norway is either recycled or burned in low-carbon incinerators to produce energy to power anything from buses to apartment buildings.

Pakistan

- Pakistan produces 6.5 million tonnes of plastic waste annually.

- Pakistan’s plastic industry has been growing at a staggering rate of 15% per year in Pakistan, which has led to the government introducing their plan of action to move towards a circular economy and achieve the UN’s Sustainable Development Goals for 2030.

- Pakistan is investing in its infrastructure to increase its capacity to collect and process plastic waste, especially PET single use drinking bottles.

- Regional bans have already been placed on the use of these PET single use bottles as they are one of the worst offending items contributing to Pakistan’s plastic pollution problem.

Poland

- Poland produces 3.4 million tonnes of plastic waste annually.

- Plastics processing is the biggest and most rapidly growing sector within the Polish plastics industry.

- Plastics processing in Poland accounts for 85% of the industry’s annual turnover; its main areas of processing include: plastic containers, bottles, packaging, pipes, automotive parts.

Portugal

- Portugal produces 1 million tonnes of plastic waste annually.

- Portugal introduced bans on several single-use plastic items from 2020, including carrier bags and cutlery.

- Portugal is behind the EU’s recycling goals for 2020, but the country did recycle 10% more waste material in 2019 than it did compared to 2018.

Romania

- Romania recycles only 14% of its waste, while upwards of 70% of the waste produced is sent to landfill.

- Romania has failed to increase the percentage of the waste it recycles since 2010 and will miss the EU 2020 targets.

- In 2018, Romania was found guilty by the EU Court of Justice for failing to close and empty 68 landfill sites that were deemed to pose environmental and health hazards.

- Romania is applying for EU grants to help them invest in waste processing technology as an alternative to landfill.

Saudi Arabia

- Saudi Arabia produces 2.5 million tonnes of plastic waste annually.

- Saudi Arabia introduced new regulations for plastic in December 2017, with the second phase coming into effect in 2020, with the use of plastic being banned for several single-use products.

- Saudi Arabia is investing in new state of the art recycling facilities to mitigate the increasing demand they are set to face; with the rapidly increasing rates of population growth and urbanisation, the amount of waste Saudi Arabia produces is forecast to double by 2033.

Slovakia

- Slovakia recycles only 23% of its waste, while upwards of 65% of the waste produced is sent to landfill.

- Slovakia will introduce a total ban on single-use plastics in January 2021; it will be illegal to sell plastic straws, cutlery, plates etc.

- This ban is part of Slovakia’s efforts to make a shift towards using biodegradable packing materials.

Sweden

- Sweden produces 300,000 tonnes of plastic waste annually.

- Sweden is one of the world leaders in recycling, having gone further than most other countries in moving towards a circular economy.

- Only 1% of Sweden’s annual waste goes to landfill; most of the waste is either recycled and sent back into manufacturing or is burned in low-carbon incinerators to produce energy to power anything from buses to apartment buildings.

Turkey

- Turkey produces 3.5 million tonnes of plastic wate annually.

- Turkey has become one of the largest importers of plastic waste as the US and Europe send more waste there since China began to close its doors to overseas recyclables, with an increase in the amount of imported plastic in Turkey of around 200% since 2016.

- Turkey’s Zero Waste Project, which began in December 2018, introduced several measures to reduce plastic consumption: for example, fees for plastic carrier bags and deposits for plastic drinking bottles.