Plastic Recycling Process

Circular Economy

Home > How We Work > Our Process

How to recycle plastic

Plastic recycling process

1. Plastic Waste Material Inspection

The process of recycling your plastic with us begins when we first hear that you have a load of plastic scrap ready and waiting to go. From the outset we are working to match it with the most well-suited recycler to get you the maximum value for your material. To help us achieve this, one of our experts will personally inspect your material before we agree a deal so that we have the best possible understanding of your product. We have over half a century’s worth of combined knowledge and understanding of polymers, and experience in recycling them, and this leaves us in the perfect position to make the best decisions on your behalf.

2. Get The Best Price For Your Plastic Waste

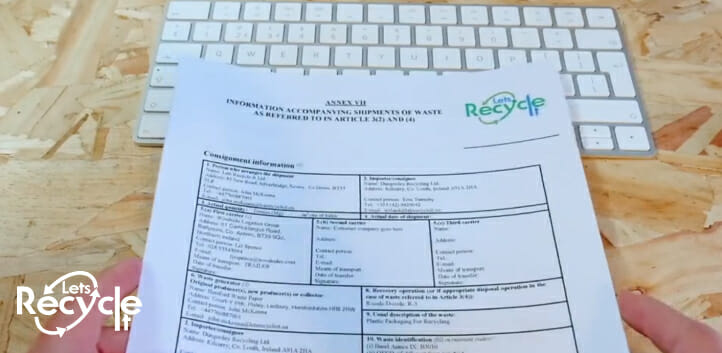

Once the ideal recycler has been found, our purchasing manager will use what we learned from our inspection to negotiate prices and logistics to get the best possible deal for you. The team at our head office will handle all of your paperwork to be certain that everything is within regulations. This ensures that everything is being done in full compliance with the industry governing bodies, so that there is no delay in your product getting to the recycler or in you receiving your payment. We will arrange logistics with our trusted hauliers who are all fully licensed waste carriers; all you need to do is load your plastic material onto the truck when it arrives, and we take care of the rest. We work only with the most reputable recyclers in the UK and across Europe in countries such as France, Spain and Turkey, who adhere to the same high standards we hold our self to. Your product will make its way to the closest recycler by road and sea; when going to Europe it will be sent in trucks that came from the mainland which would otherwise be travelling back empty, minimising the carbon footprint of the vehicles’ journeys. Once your plastic scrap has been processed by our recyclers it will be given new life in the form of automotive parts, food packaging, medical equipment and many other products across a variety of industries.

3. Environment Friendly Plastic Recycling

The process of recycling your plastic with us begins when we first hear that you have a load of plastic scrap ready and waiting to go. From the outset we are working to match it with the most well-suited recycler to get you the maximum value for your material. To help us achieve this, one of our experts will personally inspect your material before we agree a deal so that we have the best possible understanding of your product. We have over half a century’s worth of combined knowledge and understanding of polymers, and experience in recycling them, and this leaves us in the perfect position to make the best decisions on your behalf.

4. Circular Economy - Plastic

Reports detailing the problems caused by plastic are becoming more frequent, and unsustainable business practices are facing increasingly strict scrutiny. Where consumers are making it clear that they want to see more environmentally friendly products, the demand for recycled materials in manufacturing is set to surpass the demand for virgin materials. The recyclers we have built relationships across Europe with depend on us to fill their machines with quality, properly sorted materials. One of the main problems facing the recycling of plastic is in products that contain mixtures of different polymers, as recyclers being unable to separate these materials limits their ability to produce high quality recycled plastics. At Let’s Recycle It we have the expertise to identify polymer groups, to know what plastics can be processed together and how to properly separate these materials at source before transportation to the recycler. Brands are becoming more aware of the impact their products’ designs have on their value as recyclables, and the positive effect the use of recyclables has in boosting the green image among consumers. Product designers are shifting towards prioritising the recyclability of the materials they use in manufacturing; they are turning to design for recycling guidelines and increasing the proportion of recyclables that they source as raw materials.

5. Get Paid For Plastic Waste.

We operate with total sincerity in what we do, and we will always strive to achieve the best outcomes for our suppliers and their material. Providing the best service in the industry is something we pride ourselves on; we offer the most competitive rate, we will arrive when we say we’re going to arrive, and you will be paid on time. Giving your waste materials a new lease on life is what we do, and we do it well. We understand that waste is only ‘waste’ if you waste it; at Let’s Recycle It, we understand that it is a resource.

Trusted & Responsible

Manufacturing Sectors We Work With

Let’s Recycle It was established to service the increasing needs of the Irish manufacturing sector, which has been experiencing solid growth year on year.

Ireland and the United Kingdom are major producers of many different manufactured goods

These are all plastic-heavy industries and we play a vital role in helping companies to achieve corporate zero waste targets. We have seen in real time the uptake of Irish and British manufactured products as a direct result of the essential services we provide.